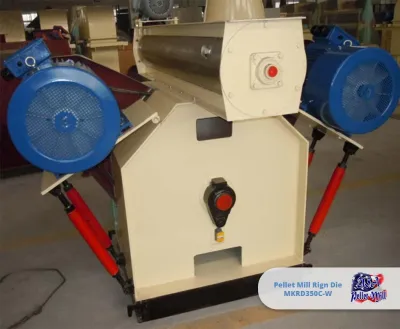

Pellet Mill Ring Die MKRD350C-W

$39524.00

Quantity

Ideal for making pellets of alfalfa, forage, biomass and/or balanced animal feed.

Technical Specifications

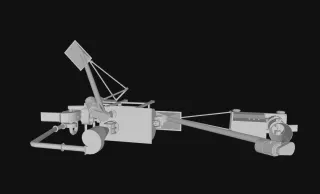

Model: MKRD350C-W

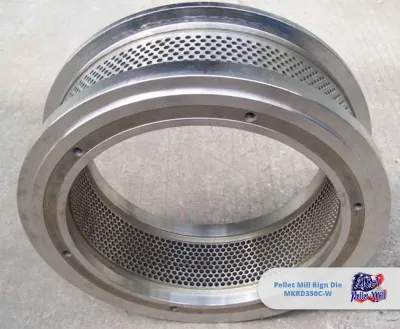

Type: Pellet Mill Ring Die

Capacity: 1540 lbs/hr wood - 3300 lbs/hr animal feed)

Power: 2 x 30 kW, 0.75kW, 0.75 kW

Power Type: Electric w/Panel

Dimensions: 85 X 77 X 75 inch

Weight: 5512 lbs

Description

These type of pellet mill is the most used in the biomass industry. The ring die form allows for all the force generated by the motor to be used to produce pellets making it a very efficient machine.

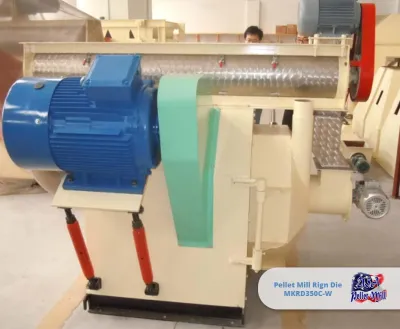

Operation: The milled raw material is loaded through the top feeder which moves the material to the front part of the machine, where a second motor powers an auger forcing the material into the rig die. This automated process makes pellets of biomass such as wood, animal feed, forage, etc. All pellets exit the machine through the bottom opening of the front cover.

Pellets come out at a temperature between 50 - 80 ºC.

Customization & Services

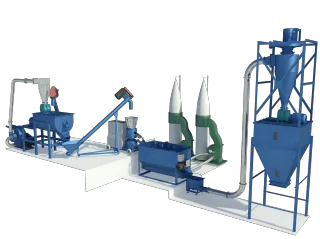

Can USA Pellet Mill build a complete pellet or feed production line?

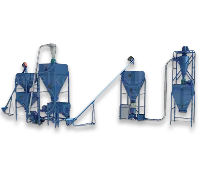

Yes. We design and supply turn-key production lines that include hammer mills, mixers, pellet mills, conveyors, coolers, dryers, and packaging systems. Each project is tailored to your raw material, production goals, and available space.

Do you offer installation and operator training?

Yes. We provide remote or on-site installation support, including detailed assembly guidance, operational training, and maintenance instructions. Our goal is to help every customer start production efficiently and safely.

Can the machines be customized to meet specific requirements?

Absolutely. We can modify capacity, motor type, voltage, die size, and layout to meet your specific production or regional electrical standards. Custom configurations ensure maximum performance and energy efficiency.

Do you supply spare parts and accessories?

Yes. USA Pellet Mill maintains a large inventory of dies, rollers, bearings, belts, and motors compatible with all our models. We offer fast worldwide shipping to minimize downtime.

Do you provide technical support after purchase?

Yes. We provide lifetime technical support for all equipment. Our engineers can assist through video calls, phone, email, or remote diagnostics. We’re committed to helping you keep your operation running smoothly.

Can you help design a plant layout or production flow?

Yes. Our engineering team can create 2D and 3D plant layouts optimized for material flow, energy use, and worker safety. We help you plan efficient pellet, feed, or briquette facilities from start to finish.

Do you offer consulting services for new pellet or feed businesses?

Yes. We provide project consulting to help new entrepreneurs estimate production costs, ROI, equipment selection, and market opportunities in the biomass or feed sector.

About Us

USA Pellet Mill CO, It is an incubator company that represents and advises manufacturers from all over the world, also distributes directly to America. We are direct manufacturers of the products that advertise on our website.

Copyright© 2025 USA Pellet Mill - All Rights Reserved.