Make your own animal food with our Pellet Mills

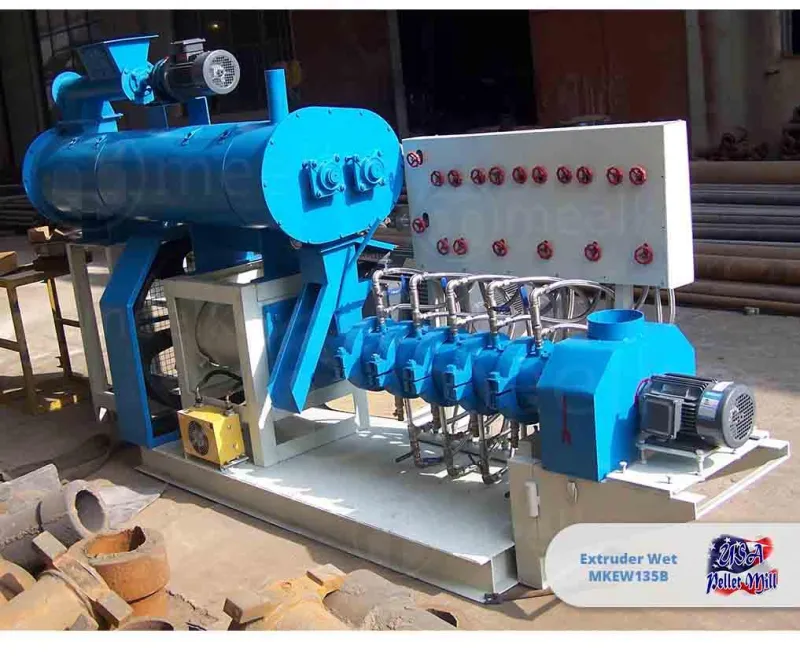

Make your own pet food with our Extruders Machines

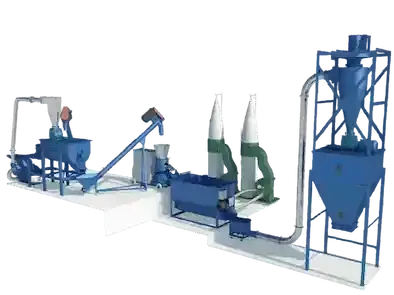

Complete Industrial Production

Lines

USA Pellet Mill Pellet Mills, Extruders & Machinery

You need it, we have it!

From pelletizing machines for food and biomass to extruders for the production of food for dogs, cats and fish.

USA Pellet Mill have what you need and we advise you in everything you need.

FAQs

What is USA Pellet Mill?

USA Pellet Mill is a U.S.-based manufacturer and global supplier of machinery used to produce feed, biomass fuel, and briquettes. From our Miami, Florida facility, we design, build, and export reliable industrial equipment to help farms, factories, and renewable-energy companies turn raw materials into profitable products.

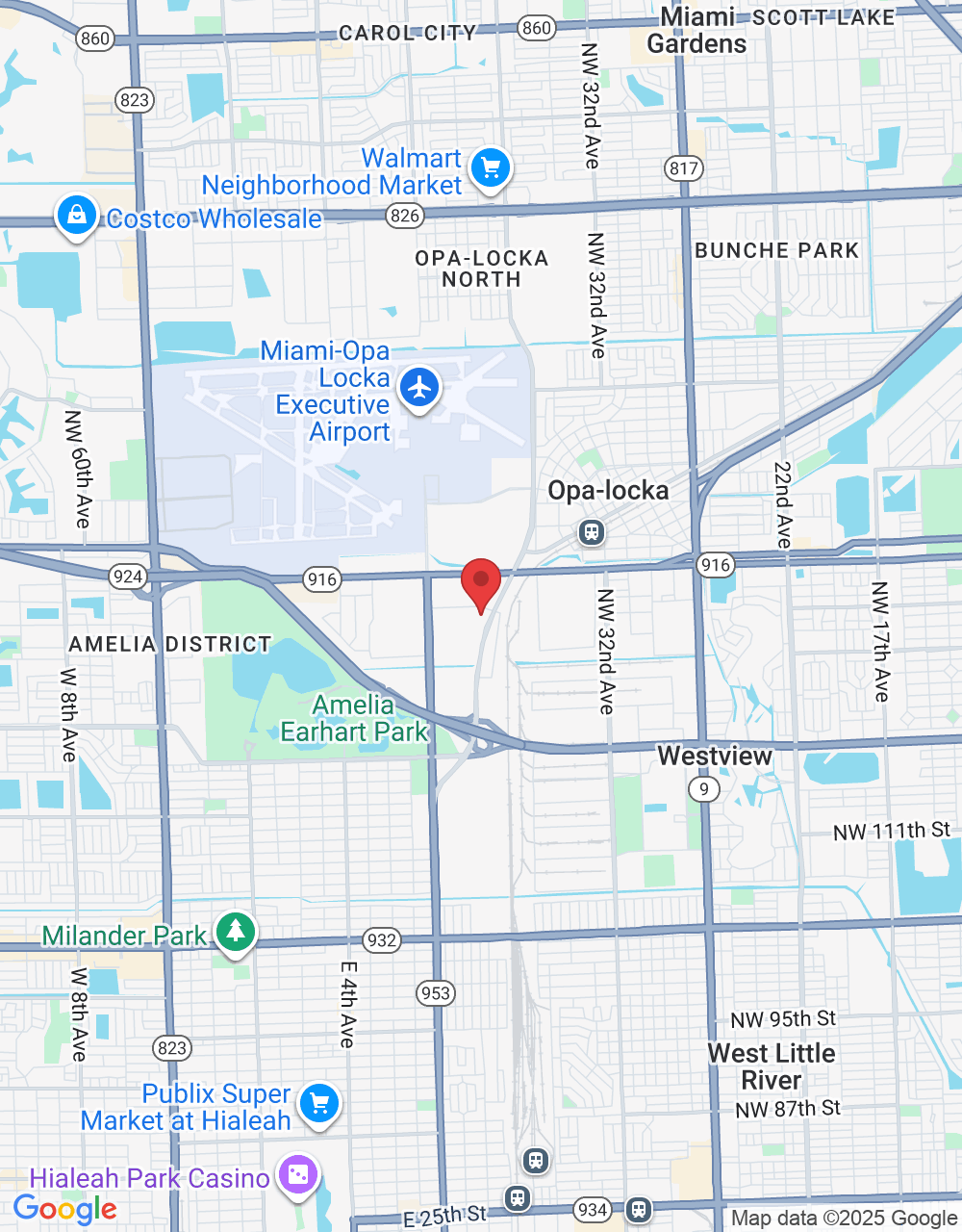

Where is USA Pellet Mill located?

We’re located in Opa-Locka, Miami-Dade County, Florida. Customers are welcome to schedule a visit or pickup appointment at our facility.

Does USA Pellet Mill ship internationally?

Yes — we ship machinery worldwide, including to Latin America, the Caribbean, Europe, Asia, and Africa. Our logistics team handles export documentation, customs paperwork, and freight coordination to ensure smooth global delivery.

What industries does USA Pellet Mill serve?

We proudly supply equipment to a wide range of sectors, including:

Agriculture & Livestock Feed – for making high-quality feed pellets.

Biomass & Renewable Energy – for producing eco-friendly fuel pellets.

Pet Food & Aquaculture – for floating or sinking extruded feed.

Fertilizer & Organic Waste Recycling – for sustainable processing solutions.

What makes USA Pellet Mill different from other suppliers?

Unlike many import resellers, USA Pellet Mill combines U.S.-based quality control with global manufacturing partnerships. This allows us to offer competitive pricing, full after-sales support, bilingual customer service, and tailored solutions for every scale — from small family farms to industrial production plants.

About Us

USA Pellet Mill CO, It is an incubator company that represents and advises manufacturers from all over the world, also distributes directly to America. We are direct manufacturers of the products that advertise on our website.

Copyright© 2026 USA Pellet Mill - All Rights Reserved.